Description

1. Summary:

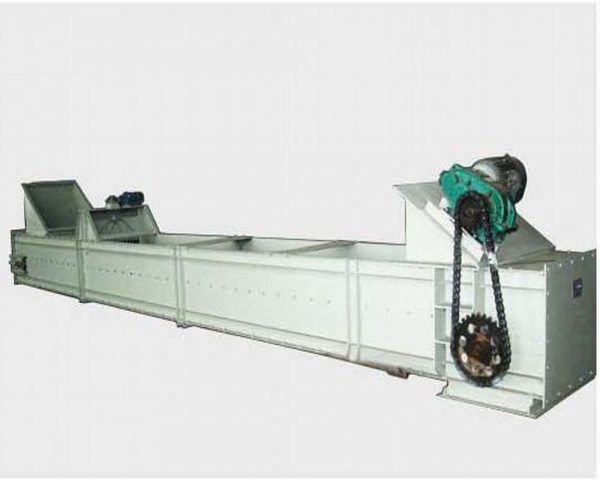

JY-2000-screw extruder is used for the dewatering of various fiber materials. Most of the water in materials can be removed, thus greatly reduced the burden on the drying machine, increased its production, and significantly reduced the energy consumption. It is the indispensable processing device for drying material with high humidity. Materials after dehydration can directly enter the drying equipment, thus the energy consumption is greatly reduced.

The screw extruder’s simple structure, easy operation, convenient maintenance and good performance make it an ideal supporting equipment for drying units.

2. Structure:

JY-2000 Series screw extruder mainly consists of motor, reducer, diameter-and-pitch-variable screw shaft, loading& unloading boxes and water filtering cage.

3. Working principle:

The material to be dehydrated is uniformly added to the extruder from the loading box, pushed by the rotary blade, move axially forward. When moving, under the action of the diameter-and-pitch-variable screw blade and extrusion head, the material forms a huge extrusion pressure, which makes the material dewatered mechanically. The moisture is discharged through a sieve in the water filtering cage, and the material after dewatering is discharged from the unloading box, so as to the dehydration can be achieved. After dehydration, the material can directly enter the dryer. Changes to the parameters of material varieties, production, and final moisture content can be controlled by adjusting the extrusion head and rotation speed of the extruder.

4. Main technical parameter:

| Model | YJ-600 | YJ-2000 |

| Power | 15KW | 18.5KW |

| Max. output capacity | 6T/H | 10T/H |

| Overall dimension | 4100×900×860 | 4760×1030×1000 |

| Weight | 2050KG | 3250 KG |