Description

CUSTOMIZED MANUFACTURING (DESIGN ACCORDING TO REQUIREMENTS)

Equipments are covering the complete dry bulk powder material industrial field. Such as the Breaking Plant, Grinder, Grading Equipment, Shaping Equipment, Mixing Equipment, Modification Equipment, Granulation Equipment, Drying Equipment, Coating Equipment, Weighing Equipment, Conveying Equipment, Iron Removal Equipment, Dust Removal Equipment and so on.

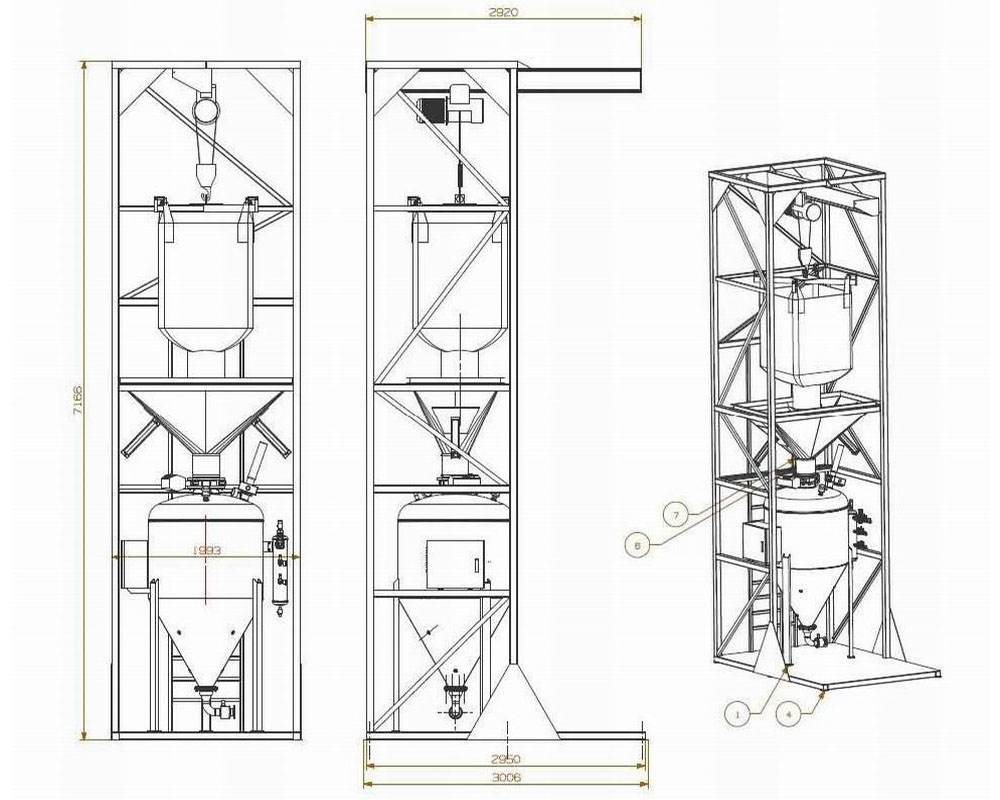

JUMBO BAG PACKING POWDER MATERIAL UNLOADING + DENSE PHASE PNEUMATIC CONVEYOR

1, Technological process

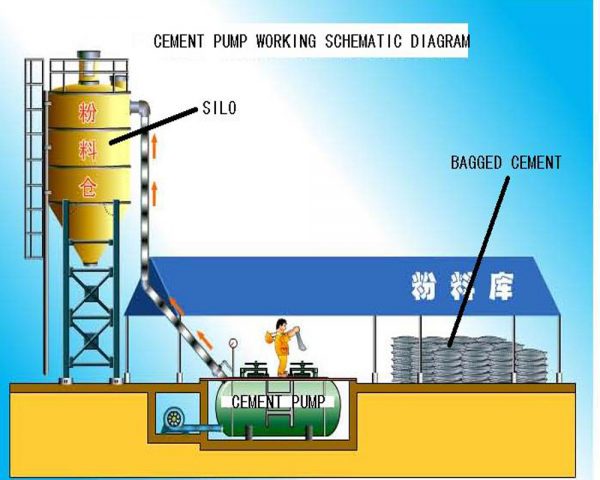

This system is suitable for long-distance delivery of talcum powder and dolomite powder. Two kinds of powder are delivered by one set of big bag unloading machine and one set of dense phase conveyor, plus one each silo top separator. They are separately delivered to different powder silos through valve switching for the purpose of delivery to two positions from the same point. We call it 1TO2 system. There would be with slight material mixing when switching due to different materials.

2, System advantage

2.1,Breakthrough intelligent delivery, with automatic anti-clogging detection function.

2.2,The impact on the material is small, low flow rate, stable delivery.

2.3,Fully enclosed operation, pollution to powder itself and environmental is very low. Particle morphology remains intact. Separated gas after purification is directly discharged into the atmosphere.

2.4,Less parts involve in rotating, so the operation is very reliable.

2.5,Small floor area, easy installation, simple operation and maintenance. For the conveyor, only need “start” and “shutdown” operations. Workers only need to patrol without watching over, thus saving labor costs. For the big bag unloading machine, if the big bag need recycle, then it need worker to unwrap the mouth rope of bag. If the big bag needn’t recycle, then it needn’t.

2.6,Advanced technology, optimized layout and ratio, low unit energy consumption.

2.7,Fluidized material transport makes the delivery a higher reliability and longer conveying distance.

2.8,The configuration of the system is flexible, and the pipeline can be flexibly arranged to a variety of terrain, so it is convenient to carry out centralized, decentralized, high altitude and long distance delivery.

2.9,Easy to adjust, with multi parameter optimization adjustment function.

2.10,Supporting facilities are simple, just need a simple compressed air supply.

2.11,All equipment has independent intellectual property rights.

3, System performance

3.1,Equipment model: PDTR1.2-25-1TO2.

3.2,Material: talcum powder or dolomite powder, big bag packaging, volume is 1.3 cubic meters.

3.3,Conveying capacity: talcum powder is more than 10 tons / hour, dolomite powder is more than 15 tons / hour.

3.4,Conveying distance: for talcum powder, horizontal distance is about 50 meters, vertical distance is about 15 meters, Less than 3 elbows. For dolomite powder horizontal distance is about 50 meters, vertical distance is about 12 meters. Less than 3 elbows.

3.5,System power: less than 5.0Kw.

3.6,Mode of operation: can be 24 hours year round.

3.7,Material: low carbon steel

3.8,Compressed air: 1.0MPa, 5.0M ^ 3 ( prepared by buyer, discontinuous operation)

4, After-sale service

4.1,Equipment warranty period: 1 year (except for wearing parts and damages caused by human factors).

4.2,For overall platform structure, provide a full set of 3D building block installation drawings.

4.3,Provide a series of documents and drawings, such as layout drawing, foundation drawing, plant frame drawing, water and electricity layout drawing, installation drawing, system specifications, and instruction manual, etc.

4.4,Installation will be made by buyer. We are responsible for the commissioning of the equipment, also assist buyer to debug the whole production line.

4.5,Assist buyers in purchasing equipment other than that provided by us.

5, Basic components of the equipment:

1 set of big bag unloading machine; 1 set of dense phase conveyor; 1 set of 1TO2 pipeline system; 1 set of intelligent anti-clogging system; 2 sets of receiver silo top separators; 1 set of intelligent control system.