Description

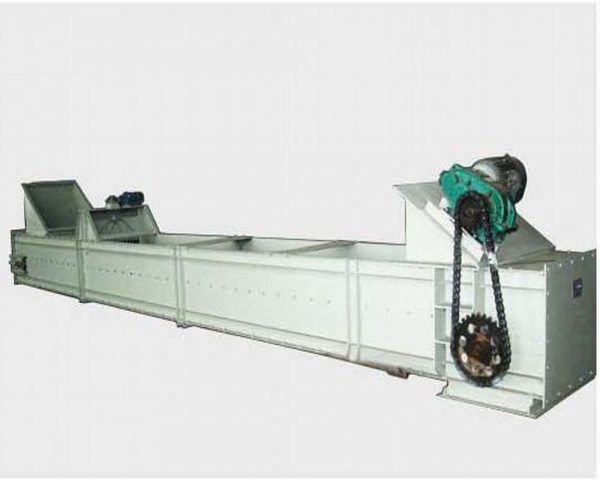

Vibration Fluidized керебет кургаткыч

Кубаттуу техникалык кучке таянып, биз кардарлардын деталдаштырылган материалдык абалына жана талаптарына ылайык жабдууларды эсептеп, долбоорлой алабыз. Колдонуучуларга эң ылайыктуу жабдууларды текшериңиз.

Иштөө принциби:

Кургаткычта эки жабдылган титирөө кыймылдаткычтары кызыктуу күчтү жаратат, бул материалдардын горизонталдык тешик пластинкасын бойлото алдыга секирет. Ысык аба тешик пластинкасы аркылуу төмөнкү бөлүгүнөн жогору карай өтөт, суусуздануу максатына жетүү үчүн материалдык катмар аркылуу өтөт.

Өзгөчөлүк:

- Энергияны үнөмдүү. Анткени материал тешикчеси аркылуу айланып өтүп, ысык аба менен толук байланышат, жылуулук натыйжалуулугу абдан жогору.

- Кеңири колдонулат. Дирилдеген кыймылдаткычтын толкундоочу күчүн жана орнотуу багытынын бурчун өзгөртүү материалдын иштөө ылдамдыгын жана иштөө абалын өзгөртө алат, ошондуктан ар кандай материалдарды кургатуу же муздатуу үчүн ылайыктуу.

- Жакшы кургатуу эффекти. Вибрация материалды секирик абалында кылат, төмөнкү бөлүгүнөн ысык аба демпфингдик таасир этиши мүмкүн, ошондуктан материал азыраак кийет, анын бузулуу көрсөткүчү төмөн, жана ашыкча ысып кетүү же агып кетүү көрүнүшү жок.

- Төмөн ызы-чуу, жакшы титирөө изоляциясы. Жабдууларды түздөн-түз полдун плитасына коюуга болот, орнотулган жана ыңгайлуу алынып салынган, жана жакшы жабылган, жакшы иштөө шартын түзүү.

- Бөлүм контейнердин ортосуна орнотулган болсо, алдыңкы бөлүгүндө ысык аба менен, жана арткы бөлүмдө муздак аба, кургатуу жана муздатуу бир эле учурда жетишүүгө болот.

- Төмөн инвестиция, төмөн иштетүү наркы, түзүлүшү боюнча жөнөкөй, бышык жана бышык, жеңил тейлөө, жеңил салмак.

- Бир калыпта жана үзгүлтүксүз азыктандырууну ишке ашыруу үчүн автоматтык материалды азыктандыруучу түзүлүш орнотулушу мүмкүн, автоматтык агым өндүрүш линиясын түзөт.Application:

Азык-түлүк, химия енер жайы, фармацевтикалык өнөр жай, тоют, пластик, туз өндүрүү, дан, үрөн, тамеки, кант, металлургия ж.

Негизги техникалык параметр:

| Кургаткычтын узундугу (мм) | Вибрация контейнеринин туурасы(мм) | Кургаткычтын туурасы (мм) | Кургаткычтын бийиктиги(мм) | Салмагы(кг) |

| 3000 | 300 | 1350 | 1700 | 1240 |

| 600 | 1650 | 1700 | 1400 | |

| 900 | 1950 | 1850 | 1630 | |

| 1200 | 2250 | 2050 | 2030 | |

| 1500 | 2650 | 2250 | 2420 | |

| 4500 | 300 | 1350 | 1700 | 1570 |

| 600 | 1650 | 1700 | 1860 | |

| 900 | 2000 | 1850 | 2430 | |

| 1200 | 2300 | 2050 | 3030 | |

| 1500 | 2600 | 2250 | 3680 | |

| 6000 | 500 | 1350 | 1700 | 1960 |

| 600 | 1700 | 1700 | 2440 | |

| 900 | 2000 | 1850 | 3160 | |

| 1200 | 2400 | 2050 | 3580 | |

| 1500 | 2700 | 2250 | 4230 | |

| 7500 | 600 | 1700 | 1700 | 3900 |

| 900 | 2100 | 1850 | 4140 | |

| 1200 | 2500 | 2040 | 5190 | |

| 1500 | 2950 | 2450 | 5940 |

Структура диаграммасы:

1.Кургаткыч 2. Азыктандыруучу кирүүчү 3.Аба чыгаруучу 4.Тилтирөө мотору

5.Тазалоочу эшик

1.желдеткич 2.жылыткыч 3.заряддоочу машина 4.ийкем түтүк 5.соргуч түтүк

6.термометр(2 даана) 7.чаң сүзгүч 8.соргуч түтүк 9.соргуч желдеткич

10.чыгаруучу розетка 11.кургаткыч 12.аба берүүчү түтүк